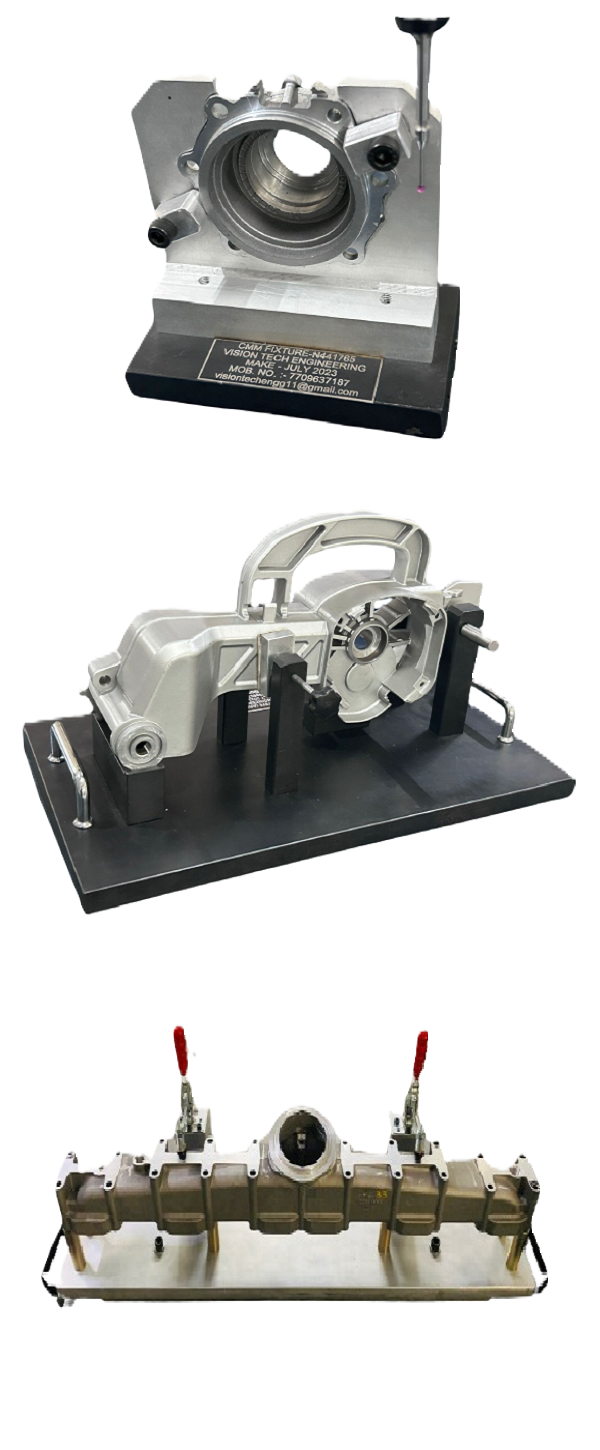

A CMM (Coordinate Measuring Machine) holding fixture is a

specialized tool used to securely hold and position parts or

components during measurement with a CMM. Here’s some key

information about CMM holding fixtures:

Purpose and Function

- Secure Positioning:

Holding fixtures are designed to stabilize and precisely position

parts on the CMM’s measuring table. This ensures that measurements

are accurate and repeatable.

- Consistent Orientation:

They maintain

the component in a consistent orientation relative to the CMM’s

probe, which is crucial for achieving reliable measurement data.

- Flexibility:

Fixtures can be customized or designed to accommodate

various shapes, sizes, and types of parts, which makes them

versatile for different applications.

Types of CMM Holding

Fixtures - Custom Fixtures:

Designed specifically for a particular

component or type of measurement. They are tailored to the unique

features of the part being measured.

- Modular Fixtures:

These use

standard components (like clamps, blocks, and plates) that can be

reconfigured for different parts or measurements. This allows for

flexibility and quick adjustments.

- V-Blocks:

Commonly used for

cylindrical parts. The part sits in a V-shaped groove that holds

it securely.

- Magnetic Fixtures:

Use magnets to hold ferrous parts

in place. They offer quick setup and adjustments but are suitable

only for magnetic materials.

- Vacuum Fixtures:

Employ suction to

hold flat or smooth parts. This is ideal for lightweight

components.

Design Considerations - Material:

Fixtures are typically

made from materials like aluminum, steel, or plastic, depending on

the strength and precision required.

- Precision:

The fixture must

be designed to ensure that the part does not move or deform during

measurement, which could lead to inaccuracies.

- Accessibility:

The

design should allow easy access for the CMM probe to reach all

necessary measurement points on the part.

- Ease of Setup:

Fixtures

should be designed for efficient setup and adjustments to minimize

downtime and increase productivity.

Applications - Quality Control:

Used in manufacturing and assembly processes to ensure parts meet

specified dimensions and tolerances.

- Prototyping:

During the

development of new products, fixtures help in verifying dimensions

and design integrity.

- Research and Development:

Used for measuring

and validating new components or technologies.